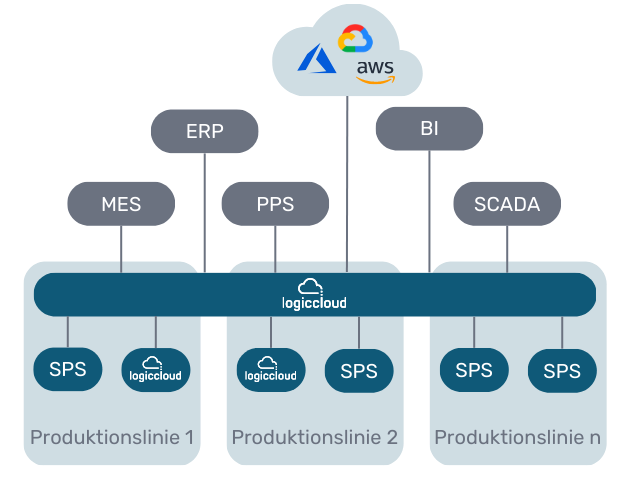

With logiccloud, control programmes for production processes can be adapted more efficiently and flexibly to changing conditions. Existing plants can be integrated into digital processes quickly and easily. All functions for production and manufacturing, material flow and logistics, product tracking can be realised with logiccloud – at the machine, in the line, at the location.

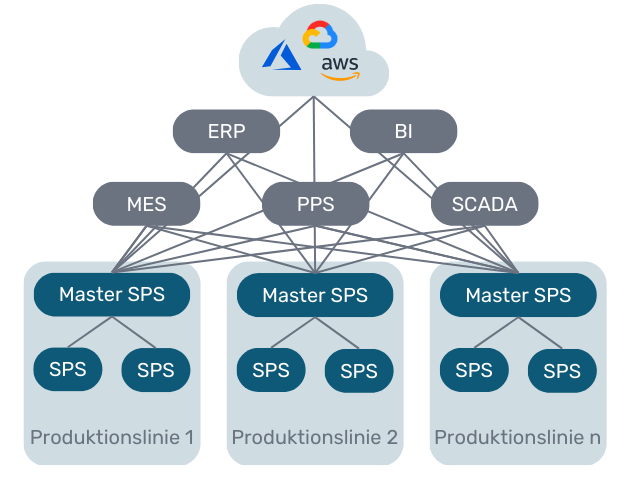

logiccloud takes over the pre-processing of process data from any number of physical or virtual PLCs, supplements this with meta-data from other systems and makes it available as uniform, consistent process information in a secure IT environment of the plant operator. Production parameters, delivery quantities, assortments, recipes or the like can thus be transmitted to all controllers simultaneously in almost real time.

Highly scalable, fail-safe control platform on the Factory Edge

Setting up flexible manufacturing and production facilities

Provision of consistent process information for e.g. ERP, MES, SCADA and AI

Entry into the Smart Factory

We answer your questions and look together how logiccloud can map your use cases and we create the greatest added value for your company.